BOPP Soft Touch Thermal Lamination Matt film For Printing Laminating

Product Description

Soft-touch thermal laminate film has a luxurious velvety finish, making it ideal for high-end products. Once laminated, it can be further enhanced through hot stamping, embossing and UV technology. It's suitable for the common offset printer printins. It's suggested to laminate the digital printings with digital soft touch thermal lamination film.

EKO a broad product portfolio by catering to a wide range of industry needs, including BOPP thermal lamination film, PET thermal lamination film, digital thermal lamination film, digital hot sleeking film, low-temperature thermal lamination film, etc. We also provide customized solutions to meet specific customer requirements, both logo and size, strengthen relationships with customers and improve customer satisfaction.

Advantages

1. Soft, velvety texture

The film provides a suede or velvet-like feel. Smooth and pleasant to the touch, it adds a high-end luxury feel to the laminate.

2. Resistant to Marks and Fingerprints

The soft-touch thermal laminate has the advantage of being resistant to marks and fingerprints. This feature helps maintain the clean and pristine appearance of the laminate, even with frequent handling.

3. Enhanced Visual Appearance

Soft-touch thermal laminations add a refined, elegant look to printed materials. It creates a matte finish that reduces glare and reflections for a more professional, premium look.

Our services

Free samples are provided if you need.

Quick reply.

ODM & OEM services to meet different requirements.

With excellent pre-sales & after-sales service.

After sales service

1. Please let us know if there's any problems after receiving, we will pass them to our professional technical support and will try to help you to solve.

2. If the problems are still unresolved, you can send us some samples(the film, your products which have problems with using the film). Our professional technical inspector will check and find the problems.

Storage Indication

Please keep the films indoor with cool and dry environment. Avoid high temp, moist, fire and direct sunlight.

It's best used within 1 year.

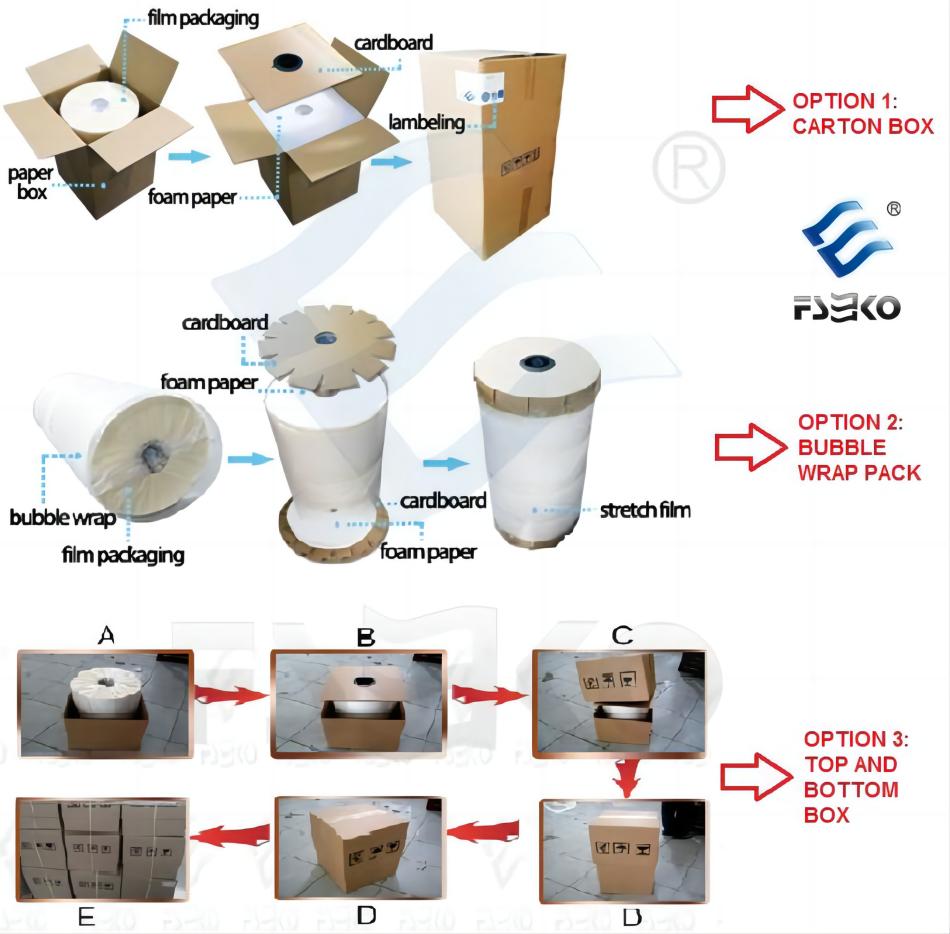

Packaging

There are 3 types of packaging for your choice

Company Profile

EKO is a professional thermal lamination films manufacturer in China, our products are exported to over 60 countries. We have been innovating for over 20 years, and own 21 patents. As one of the earliest BOPP thermal lamination film manufacturers and investigators, we participated in setting pre-coating film industry standard in 2008. EKO prioritizes quality and innovation, always putting customer needs at the forefront.